As they say in the marketing world, “People don’t want to buy a quarter-inch drill. They want a quarter-inch hole.”

While there is a lot of old wisdom attached to this particular quote, I have found that it applies to me in the literal sense as well. Indeed, I am not looking for a drill bit for the sake of it. I need one that is fit for the job.

Throughout the years, I have realized that drill bits are sacrificial by nature. I often curse the drill bits in my toolbox for bending, breaking, getting dull, and of course, for disappearing without a trace for weeks on end.

During those weeks of the drill bit going MIA, I completely forget about its existence until I face a task that only the missing tool can finish. Whether out of necessity or laziness, I resort to using any other drill bit that even remotely resembles the one I need.

But, of course, the results aren’t always the best. Hi! I’m Stacy, and here’s what you need to know about the different types of drill bits and uses so that you can achieve great drilling results every time.

9 Types Of Drill Bits And When To Use Them

1. Twist Drill Bits

My first drill bit was a universal twist bit – and I still go back to it often for most of my DIY projects. That said, most twist drill bits are well-suited for drilling wood, plastic, and steel.

As the name suggests, these bits have a twisted flute. Often made with high-speed steel., they may come in thin and long rods or stubby forms. Either way, it is rare to find a twist drill bit made of soft material.

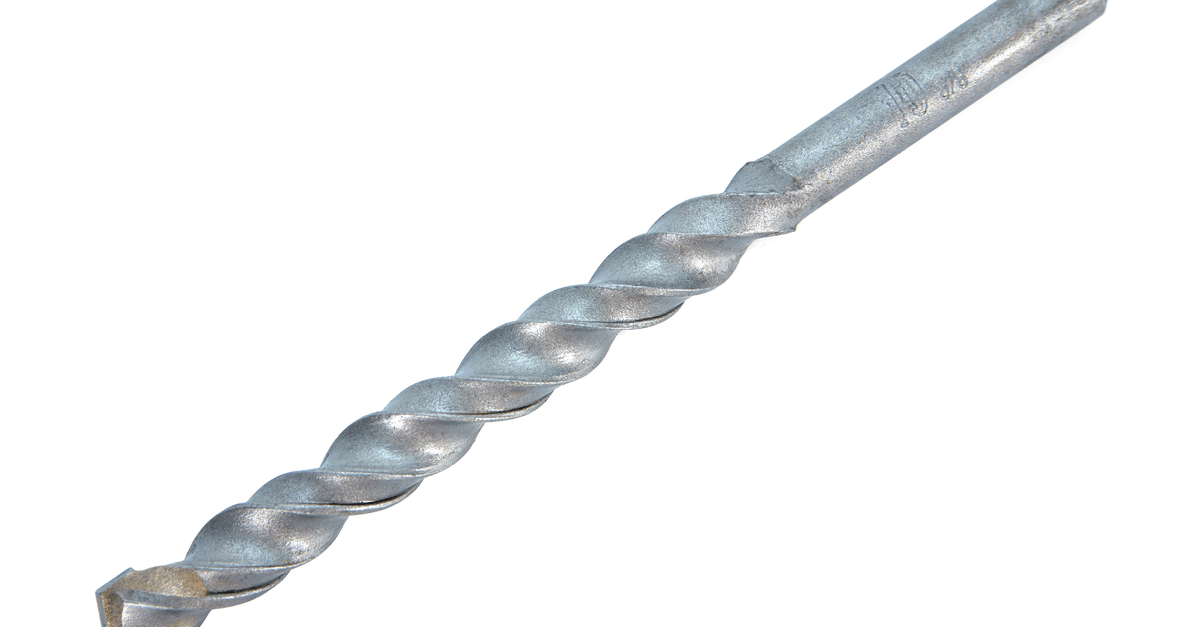

2. Masonry Drill Bits

Any wild guesses on what to use this with? That’s right – masonry bits work best on bricks and mortar. They also work exceptionally well on stone, concrete, and block but do not lend much when used on steel and wood due to their blunt tips.

That said, you can quickly identify a masonry drill bit by its lack of cutting edge and a tip that is wider than the shank. Unlike most other sharp-tipped bits, this tool utilizes a crushing rather than a cutting mechanism. Due to this action, it is prone to wear and requires frequent changes.

3. Dowel Drill Bits

Apart from brick and steel, I often work with wooden materials. That said, for most of my cabinets and other wooden furniture, I usually go for the dowel drill bit. Also known as the lip and spur bit, it resembles the twist drill bit and utilizes a similar mechanism.

However, upon closer inspection, you may notice that the cutting edges are angled to work in the opposite direction of twist drill bits. What’s more, I have seen that it forms much cleaner holes on wood and is primarily ineffective on metal and plastic.

4. Straight Fluted Drill Bits

Even as a beginner, the straight fluted drill proved to be an easy tool to work with. Almost exclusively used for non-ferrous metals, such as copper and brass, it is well-suited for softer materials.

Instead of the spiral flutes characteristic of twist drill bits, straight fluted drill bits feature two straight flutes, which do not grab or pull the surrounding material. As a result, there is less chance of breaking and chips flying around while drilling.

5. Countersink Drill Bits

Want to drill a rose or star-shaped hole? Try out the countersink drill bit. Although there is some aesthetic beauty to the shallow holes dug out by these drill bits, its purpose is not entirely superficial.

Indeed, this multi-fluted drill creates a recess that can snugly fit a counter head screw. You may use a larger twist drill bit as an alternative to countersink drill bits, but the head screw may not fit into the drilled hole as perfectly.

6. Step Drill Bits

This versatile little tool looks like a cone with descending steps. That said, you can increase the diameter of the hole you are drilling by pushing the step drill further down. Unfortunately, this tool is only well-suited for sheet metal and soft materials.

Interestingly, the drill bit doubles up as a deburring tool that you can use for smoothening drilled holes.

7. Flat Drill Bits

Usually made of high-carbon steel, flat drill bits are easily recognizable by their flattened cutting edge, which is, in fact, formed by tempering, hammering, and hardening. These tools have been around for a long time, and despite being low-performance drill bits, they are here to stay.

That said, flat drill bits are one of the cheapest drill bits on the market and may be used to form holes on wooden materials and soft metals. However, don’t expect a neat hole while using this tool.

8. Auger Drill Bits

If you indulge in woodworking often and don’t have access to an electric drill, an auger drill bit might be just what you need. All you need to do is attach it to your brace, and it bores easily into thick wooden material without requiring much pressure.

9. Tile And Glass Bits

If you feel adventurous and want to drill through tile and glass, take a look at these spear-like drill bits. However, I must warn you that the tip tends to wander around until a hole has been established.

- DEWALT 21-pack black oxide twist drill bit set is ideal for general-purpose drilling materials like metal, hardwood, softwood, PVC and fiberglass

- Parabolic flute design increases chip ejection in metal and wood drilling applications

- Black oxide coating helps resist corrosion and increase durability, so your drill bits last longer

- 135 Degree Split point tip design to help reduce walking

- High Speed Steel to be used in plastic, wood, and metal

- Tapered web design for extreme durability and resisting breakage

Final Words

I have met many machinists in my life and even got married to one. Although my husband and I argue on many things, including which drill is best suited for what job, a compromise is always made by picking a universal twist drill.

Indeed, this is an excellent place to start for beginners and DIY enthusiasts. However, don’t hold yourself back; go ahead and try out the plethora of drill bits on the market that have been designed for different uses.

Perhaps slowly, but surely, you will realize how using the proper drill for a specific job will reap polished and professional results. Soon enough, you may even rack up a collection of drill bits for every occasion imaginable. Or should I say – a drill bit for every bit of your needs!